How to Purchase the Right Boiler Grate Bars During Maintenance?

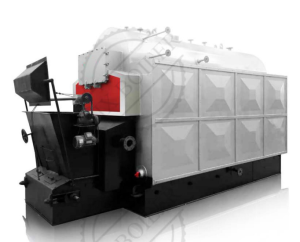

Boiler grate bars are critical components directly involved in fuel combustion, widely used in chain grate steam boilers, hot water boilers, thermal oil boilers, and other thermal equipment. To ensure the boiler operates efficiently, regular inspection and maintenance of the chain grate and its components are essential.

Common Chain Grate Issues and Solutions

- Chain Grate Movement Failure: Large fuel particles or external forces can cause the grate to jam, leading to intermittent movement or complete stoppage. Severe cases may result in broken fuse links or damaged transmission mechanisms. Immediate inspection and troubleshooting are required

- Chain and Gear Misalignment:Prolonged operation can cause significant wear, leading to misalignment. Timely chain replacement is necessary.

- Chain Beam Bending: External forces or overload can bend the beams, requiring immediate replacement.

- Grate Deviation During Operation: Improper adjustment of the front and rear axles during installation can cause unstable grate movement.

- Fuel Coking on the Grate: Long-term use of low-quality coal or high-oil-content fuel can lead to caking on the grate surface. Regular cleaning is recommended.

Purchasing New Chain Grate Spare Parts

When replacing essential parts like grate bars, it’s crucial to provide suppliers with accurate details to avoid confusion. Below are key measurements for a 20t/h chain grate steam boiler:

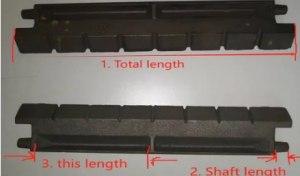

1. Left and Right Boiler Grate Bars

Measure the length, width, height, and positioning dimensions. Note that left and right bars may look similar but have different installation orientations.

2. Middle Grate Bar

Provide detailed measurements as illustrated.

3. Large Grate (Fish Scale Type)

Due to variations between manufacturers and batches, measure the length, width, height, hole spacing, hole diameter, and other parameters.

4. Chain

Specify the length, number of sections, thickness, and other requirements. For example, a 20m chain with 125 sections.

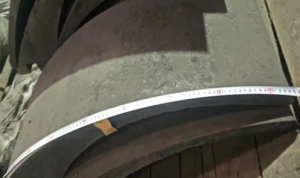

5. Boiler Slag Stopper/Ash Remover

Measure the arc length and the distance between endpoints.

6. Roller

Provide the overall length.

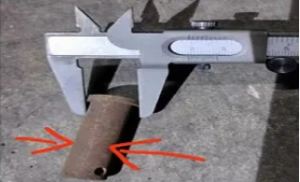

7. Bushing

Include outer and inner dimensions.

8. Shaft

Specify the dimensions and overall length.

9. Grate Buckle

Provide the end face diameter and connecting part diameter.

10. Side Seal Plate

Measure the overall length, height, and width, as designs vary.

Summary

By providing the above data to suppliers, you can easily purchase the correct parts. If unsure, feel free to contact Boiler Philippines for professional assistance.

About Boiler Philippines

As a leading boiler manufacturer, we offer high-quality products at competitive prices. Our equipment is rigorously inspected and packaged to ensure superior performance.

Our Products Include:

- Steam Boilers: Coal-fired, biomass, gas/oil-fired, electric, and more.

- Thermal Oil Boilers

- Chain Grate Stokers, Grate Bars, and Related Components