The boiler industry offers a wide array of choices, each utilizing different energy sources. While not every boiler is as cost-effective as a wood-fired boiler, the latter has become increasingly popular, especially for industrial and commercial purposes. The question remains: Why are small wood-fired steam boilers so well-received? The short answer lies in their affordable energy utilization. But that’s not all. Let’s delve deeper into this specific boiler type. After reading this guide, you’ll have a comprehensive understanding of the system. So, let’s get started!

What is a Small Wood-Fired Steam Boiler?

You may have noticed the use of the word “small” in wood-fired steam boilers. This is because small sizes are typically the standard choice for commercial and industrial settings. These boilers primarily use wood as their power source, with inputs such as wood chips, pellets, raw wood, or wood offcuts. However, it’s important to note that these boilers don’t necessarily have to rely solely on wood; they can also utilize other energy sources like coal and natural gas. In fact, most industries prefer systems that offer multiple energy options, as it enhances flexibility, convenience, and cost-effectiveness.

Efficiency

Another common question concerns the efficiency of wood-fired boilers. Typically, these systems can achieve up to 90% efficiency. However, this rate depends on factors such as boiler design, additives, additive quality, and heat loss. Many inexperienced individuals mistakenly equate boiler efficiency with combustion efficiency. The latter only defines the efficiency of a single process. Wood steam boiler efficiency, on the other hand, measures everything from input to output. This is why combustion efficiency can reach as high as 99%, while the system’s overall rate may be affected by other input-related operations.

History and Evolution

Boilers underwent revolutionary changes in the 1900s, with most modern fossil fuel sources discovered during that century, including coal, oil, and wood. Wood-fired boilers gained prominence in the 1970s, thanks to Professor Richard Hill, often hailed as the mastermind behind wood-fired boilers. His model featured an independent fan, secondary air unit, and water-based heat storage device, along with two combustion stages to enhance efficiency. Since then, multi-fuel wood boilers have become prevalent, utilizing both wood and oil in their heating chambers. The 1980s witnessed the rise of ingeniously designed wood-fired boilers. Today, these systems incorporate advanced technologies in their design and auxiliary equipment to maximize efficiency.

Components and Auxiliary Equipment of Small Wood-Fired Steam Boilers

The composition and design of small wood-fired steam boilers may vary depending on the manufacturer, input and output capacity, and energy compatibility. However, certain components and auxiliary equipment are common across all wood-fired generators. Let’s take a closer look at them and their functions:

1. Fans

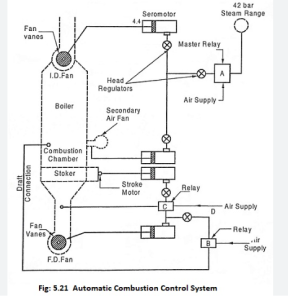

Fans play an indispensable role in boilers. They provide the necessary air pressure and cooling functions within the system. Typically, generators require a certain amount of air pressure to operate, which is where forced draft fans come into play. They are usually installed as a single unit in wood-fired boilers, generating mechanical air pressure to maintain the environment. Additionally, induced draft fans provide negative air pressure by evacuating system space through combustion output absorption. Lastly, auxiliary fans, though optional, are highly recommended for wood-fired boilers, extending the functionality of induced draft fans by maintaining a viable environment.

2. Combustion Chamber

The combustion chamber is the core component of a wood-fired boiler. Constructed from fire-resistant bricks, it houses the intense flame that burns the input wood chips, pellets, or leftovers. However, you can always control this chamber, adjusting the temperature according to the boiler’s range.

3. Grate

The grate is arguably the most understated component of a wood-fired boiler system. It serves as the platform for igniting the input wood. In essence, it keeps the flame contained within the combustion chamber. Typically made of cast iron, grates can withstand high temperatures.

4. Economizer

An economizer can be a primary or additional component, but it’s something you should consider installing in your boiler. Why? Because it directly enhances system efficiency by recovering heat that would otherwise be wasted through heat loss. It utilizes this heat during boiler operation to maintain the recommended temperature.

5. Discharge Machine

After obtaining the desired output, you’ll need assistance in removing it from the system. This is where the discharge machine comes into play. It helps unload the combustion products into your storage unit, ensuring optimal output without waste.

6. Deslagging Agent

Wood-fired boilers can operate at very high temperatures, leaving behind some burnt slag in the system. A deslagging agent is the device for this task. It effectively removes boiler by-products and features a pre-installed water-cooling system to prevent damage from hot slag.

7. Steam Header

The steam header is essentially a set of pipes that help expel unwanted steam from the system. Otherwise, it could damage the boiler and affect its operation. These pipes feature an efficient design and a durable reinforced steel body.

8. Dust Bag

Dust bags are an excellent alternative to manual cleaning. They collect all unwanted particles from the system, keeping your boiler in a filtered state and preventing dust from reducing efficiency.

9. Chimney

Chimneys play an environmental role in boilers. They eliminate all combustion flue gases without affecting your work environment. Also known as steel bags, they release these gases at heights that do not pollute the atmosphere. Chimneys are highly recommended components to ensure the safety of boiler operators.

Can You Obtain Spare Parts for Small Wood-Fired Steam Boilers?

Small wood-fired steam boilers are more prominent than ever in today’s industrial and manufacturing sectors. Much of this credit goes to their convenience. Their maintenance and repair are easier compared to large wood-fired boiler systems. So, can you obtain spare parts for these boilers? The short answer is yes. However, you must consider the following factors:

Compatible Spare Parts

Remember, not every boiler component is replaceable. Moreover, manufacturers do not carry every part of the system. Nevertheless, some common spare parts are readily available in the market, including safety valves, pressure gauges, blowdown valves, shut-off valves, three-way cocks, check valves, water level sensors, grates, and pipes.

Manufacturers and Their Policies

Many manufacturers do not provide spare parts; they mention this in their policy documents, manuals, etc. However, many other companies, such as Boiler Philippines, offer free spare parts as long as your system is under warranty. Afterward, they may charge you for the components. Alternatively, many manufacturers’ warranties do not cover spare parts, meaning you must purchase them directly. Otherwise, opt for a reliable third-party seller with quality auxiliary tools.

Maintenance of Small Wood-Fired Steam Boilers

Assuming you’ve purchased a small wood-fired steam boiler, how will you maintain it? This can be challenging, especially for beginners. However, maintenance is relatively straightforward. Here’s what you need to do:

1. Regular Inspections

Your system requires frequent inspections to avoid larger issues. Regular inspections are strongly recommended to prevent additional expenses. Many believe professional inspections are necessary, but that’s not the case. All you need to do is ensure the system operates efficiently. Monitor its liquid level, working temperature, and efficiency through sensors and testers. You should also look for gas leaks and heat loss, checking components such as the combustion chamber, pipes, chimney, and gaskets.

2. Cleaning

Even if your system has cleaning components like dust collectors, prioritize cleaning. However, this doesn’t mean sterilizing the boiler after each use. Simply check its cleanliness monthly. Ensure the removal of unwanted particles from the chamber, chimney, economizer, and discharge machine. Remember, most boiler problems can be resolved through frequent cleaning.

3. Recalibration

Calibration involves setting the boiler’s operating conditions. These settings ensure your system works effectively and stops running when provided conditions are unsafe. Ultimately, this simple step can help extend the boiler’s lifespan. However, calibration may be canceled over time, especially in older boilers. Consider recalibrating your system every six months or year.

4. Safety Measures

When operating a high-end system, your safety is equally important. Remember, these boilers operate at higher temperatures. Always double-check safety measures, including valves, smoke alarms, and temperature controls. Experts recommend monitoring these aspects weekly to prevent workplace accidents. Lastly, ensure your boiler complies with regional safety standards.

Should You Purchase a Small Wood-Fired Steam Boiler?

Yes, a small wood-fired steam boiler can meet your industrial needs for the following reasons:

- Higher Efficiency: Wood-fired boilers can achieve up to 90% efficiency, with combustion efficiency reaching 99%. They are among the most efficient wood-fired steam generators for industrial applications. To maintain this rate, all you need to do is conduct regular inspections, cleaning, and install necessary auxiliary equipment.

- Capacity Range: Despite their small size, these boilers are powerful. They can provide a maximum output of 1400 kW, meaning you can obtain a small system with a maximum size of 2 tons.

- Obstacle-Free: Their small size makes them more suitable for indoor installation, a significant advantage for small industrial and commercial spaces. Additionally, their installation is cheaper and more convenient than large boilers.

- Safety Measures: Since they operate at higher temperatures, these systems offer all essential safety measures. You can obtain durable valves, pipes, gaskets, and chimneys, ensuring a safe environment and efficient boiler operation for years.

- Cheaper Energy: Wood is a relatively inexpensive energy source, more accessible than fuel, natural gas, and coal. The best part is that these boilers can accept various forms of wood input, including chips, pellets, raw wood, lumber, or leftovers.

- Multi-Energy Input: Many small wood-fired boilers may feature multi-energy input, allowing you to combine wood with other sources like coal, oil, or biomass.

How to Purchase a Small Wood-Fired Steam Boiler?

Are you looking to buy a small wood-fired steam boiler? Consider the following factors: input and output range, components and auxiliary equipment, design, size, and installation guarantee. If you choose a reliable manufacturer like Boiler Philippines, you can overlook most of these factors. We offer free spare parts, efficient boilers, installation assistance, after-sales service, and quality auxiliary equipment.

Conclusion

Small wood-fired boilers can be the ultimate solution to meet your industrial needs. They can handle operations more effectively than many other generators. Additionally, their design makes them superior in terms of installation, efficiency, and convenience compared to other types. A professional tip for this system is to always consider inspections and maintenance. This simple step can save you from more significant problems and expenses in the long run. Choose Boiler Philippines for the best deals on small wood-fired steam boilers, as we exclude intermediary costs. Moreover, our catalog is extensive, offering many options in this category, allowing you to easily find a product that suits your industrial or commercial requirements.

Visit us at http://www.boiler.ph for more information.