Ultimate Guide to Wood-Fired Steam Boiler Efficiency

Wood-fired steam boilers have become a standard for industrial applications. They offer numerous advantages, such as affordable and renewable energy. Additionally, their ease of installation and operation makes them accessible to small and emerging industries. But the question remains: Are these boilers efficient? Many assume that wood-fired generators might be inefficient due to their lower cost, but this isn’t necessarily true. This guide will help you understand the efficiency of wood-fired steam boilers.

What Does Boiler Efficiency Mean?

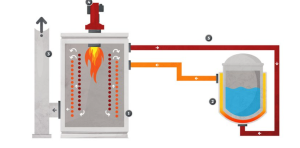

Let’s start with the basics. Boiler efficiency measures how effectively the system converts input energy into output. It defines the transformation of fuel into heat, steam, or warm oil. The better the boiler performs, the higher its efficiency.

What Makes a Boiler Efficient?

An efficient boiler is one that uses minimal input to produce optimal output. However, efficiency depends on several factors:

- Design: Poor design can lead to longer transfer times between components and wasted fuel.z

- Fuel Type: The type of fuel used impacts overall efficiency.

- Operation: How the boiler is operated also plays a role.

How to Calculate Boiler Efficiency

You can determine boiler efficiency using the following formula:

Most boilers come with chimneys to support continuous evaporation. The evaporation ratio is another critical factor:

For a more scientific approach, use this formula:

Boiler Efficiency (%) = [Q × (H – h) / (q × GCV)] × 100

- Q = Heat output

- H – h = Steam enthalpy – Water enthalpy (measured in kcal/kg)

- GCV = Gross Calorific Value

Why Is Wood-Fired Steam Boiler Efficiency Important?

1. Energy Efficiency

Inefficient boilers require more fuel input for unsatisfactory output, leading to higher fuel costs. Efficient generators maximize output from the given input.

2. Cost Reduction

Inefficient boilers need more maintenance due to component wear and tear. Efficient systems, with streamlined designs, require minimal repairs and upkeep.

3. Environmental Impact

Inefficient systems emit more harmful gases, increasing their carbon footprint and harming the environment.

How Efficient Are Wood-Fired Steam Boilers?

Efficiency depends on several factors:

- Fuel type (wood chips, pellets, scraps, etc.)

- System design

- Quality of auxiliary components

- Reliability of main parts

- Compliance with industry regulations

Under poor conditions, wood-fired boilers may operate below 50% efficiency. However, with proper handling, they can achieve up to 90% efficiency. Well-designed steam generators typically offer 80-86% efficiency, but regular maintenance is crucial for optimal performance.

How to Improve Wood-Fired Steam Boiler Efficiency

1. Use High-Quality Auxiliary Components

Upgrading auxiliary parts, such as dust collection bags or automated control panels, can enhance efficiency.

2. Keep the Boiler Clean

Regular manual cleaning ensures cleaner steam output and reduces component wear.

3. Install ID/FD Fans

These fans improve airflow, optimizing conversion rates and preventing overheating.

4. Insulate Valves

Uninsulated valves lead to heat loss and uncomfortable working conditions. Proper insulation is essential.

5. Schedule Regular Inspections

Professional inspections help identify and fix issues before they affect efficiency.

With proper care, wood-fired boiler efficiency can improve by 6-10%, potentially reaching up to 90%.

Heat Loss and Its Impact on Efficiency

Causes of Heat Loss:

- Poorly insulated components

- Inefficient chambers or furnaces

- Overheating due to inadequate cooling

Effects of Heat Loss:

- Reduced output

- Unworkable environments due to high temperatures

- Component damage and system failures

How to Minimize Heat Loss:

- Insulate valves and pipes.

- Ensure fans and cooling systems are functional.

- Avoid overloading the boiler.

- Use auxiliary cooling devices.

- Conduct regular system checks.

Key Notes About Wood-Fired Steam Boiler Efficiency

- Efficiency testing standards vary (e.g., U.S. vs. EU methods).

- Wood pellet boilers are generally more efficient than wood chip boilers.

- Claims of 99% efficiency are unrealistic due to unavoidable heat loss.

- Test methods for efficiency calculations may not always be accurate.

- Lower Heating Value (LHV) and Higher Heating Value (HHV) yield different efficiency results.

Choosing an Efficient Wood-Fired Steam Boiler

Investing in a high-quality boiler from a reliable manufacturer is the best way to ensure efficiency. Boiler Philippines offers a range of high-performance steam boilers, including wood-fired models, designed for industrial applications.

For more details, visit: http://www.boiler.ph

Conclusion

This guide covers everything you need to know about wood-fired steam boiler efficiency, from calculations to improvement tips. Regular maintenance and professional inspections are key to sustaining high performance. For the best results, choose a trusted supplier like Boiler Philippines to maximize fuel savings, optimize output, and minimize future issues.

About Us

Boiler Philippines is a leading steam boiler manufacturer with decades of experience in delivering high-efficiency solutions. Our oil/gas boilers achieve up to 98% efficiency, while coal/biomass boilers reach 85%. We are committed to providing cost-effective and reliable steam boiler systems for industrial applications.

Our Products:

Coal-Fired Boilers

Biomass Steam Boilers

Thermal Oil Boilers

Vertical Boilers

For inquiries, visit: http://www.boiler.ph