Checking All Components Before Ignition

When it comes to coal steam boiler ignition, certain precautions must be taken.

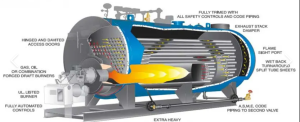

First, ensuring proper boiler ventilation is crucial. In coal-fired steam boiler ignition requirements, the flue must remain unobstructed without any blockages. Additionally, inspect the boiler for any potential leaks or cracks.

Check the fuel to ensure its quality is good and suitable for use in coal-fired boilers. The fuel should be properly stored and handled with necessary safety precautions in mind.

Inspect the area surrounding the boiler to ensure it’s free from fire hazards. It should contain no combustible materials and have adequate water supply nearby for emergencies.

Take necessary precautions to prevent coal fires. This means the boiler should never be left unattended while operating, and the fire should be constantly monitored. Furthermore, the boiler should undergo regular maintenance to ensure it functions properly and safely.

Initial Preparation for Boiler Ignition

Before igniting a coal steam boiler, pay close attention to the attachments and pipelines. Conduct a thorough inspection before beginning the ignition process. Ensure the drain valve is closed before adding water. Open the top valve of the upper drum to allow air to escape from the boiler. Treated water should be gently pumped into the boiler through the coal-fired steam boiler economizer, with the water temperature typically not exceeding 40°C.

Since coal’s ignition point is approximately 300°C, another ignition source is needed to start combustion. Open the ignition door and add ignition materials like firewood (nails are strictly prohibited) in front of the furnace to ignite. Open the induced draft fan’s flue gas damper to enhance natural ventilation.

Ignition Process and Monitoring

After the ignition materials in the steam boiler begin burning, adjust the flue damper and occasionally activate the induced draft fan. Once the ignition materials have burned through, gradually increase the grate speed and feed quantity, then turn on the forced draft fan. Close the ignition door and increase observation of the fire through the left inspection hole. When the fuel layer burns vigorously, it’s suitable for spreading the fire.

To ensure proper combustion of the fuel layer, adjust the opening degree of the air doors on both sides of the grate. Regulate the forced air volume to maintain negative pressure in the furnace at around 20Pa. To prevent excessive thermal stress in different parts of the boiler that could affect its lifespan, the time from cold furnace ignition to reaching working temperature should be 10-12 hours. For subsequent ignitions, except under special circumstances, a cold furnace should take no less than 5 hours, and a hot furnace no less than 1 hour.

Check if the coal steam boiler’s ignition pressure reaches 0.2 to 0.3MPa, and inspect whether the manhole and handhole covers leak. If they do, tighten the bolts on these covers and ensure the drain valve is secure and leak-free.

Pressure and Temperature Monitoring

During steam boiler ignition, note that as internal pressure increases and temperature rises steadily, boiler components should not make unusual sounds. If abnormal noises occur, promptly investigate the cause and, if necessary, stop the boiler to inspect and correct the issue before continuing.

Additionally, during boiler ignition, monitor the water temperature at the fuel tank outlet. At working pressure, the water temperature should be 40°C below the saturation temperature. If it exceeds this limit, close the valve leading to the economizer boiler pipe, open the recirculation valve to the economizer water tank, and supply water to the economizer.

Conclusion

Ensuring compliance with all safety protocols is crucial, including proper ventilation, correct fuel handling, and regular maintenance. Following these precautions will help Boiler Philippines ensure safe and efficient operation of coal-fired steam boilers.