This is one of the prime reasons that make them the best choice for buyers, but that’s not all. There are numerous other reasons that compel you to choose industrial wood steam boilers over any other steam boiler. Let’s read this article to understand wood-fired boilers and their design briefly for better knowledge of their working. Then we’ll read the 5 best reasons to replace your boiler with an industrial wood-fired steam boiler.

Understanding Industrial Wood Steam Boilers

Before we proceed to the reasons for choosing industrial wood steam boilers, let’s understand what an industrial wood steam boiler is. It’s a type of biomass boiler that uses wood as fuel. You can use wood waste from your own industry (if available) and save on fuel costs.

Wood waste comes in several forms and shapes like logs, pellets, chips, etc. Similarly, industrial wood steam boilers have different designs depending on the consumption of each wood waste type. They can be wood pellet boilers or wood chip boilers, referring to their fuel consumption.

Design and Manufacturing

Wood-fired boilers come in various sizes and dimensions. Their combustion chambers, furnaces, and tubes also vary, but what makes them the same is their operating power. These boilers operate with high efficiency, up to 95% with operating pressure ranging between 180 psi to 350 psi.

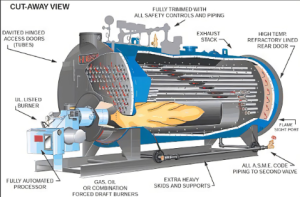

Let’s enlist the main components of an industrial wood steam boiler to see its design. The main components of any wood-fired steam boiler include:

- Wood waste bunker

- Mobile fuel auger

- Metering box

- Stoker auger

- Combustion chamber

- Ash removal system

- Boiler tubes

- Economizer

- Emission test port

5 Best Reasons to Choose Industrial Wood Steam Boilers

1. Safer Than Other Steam Boilers

Safety is the prime consideration of any wood-fired boiler manufacturer. Since a boiler is a continuous heating machine, it needs proper handling and care to avoid inconvenience or damage. Industrial wood steam boilers have robust designs that make them capable of withstanding extreme temperatures and pressure.

Wood steam boilers are safer than other boilers due to their dual combustion chambers. These dual chambers allow proper heating while maintaining the optimal amount of oxygen to keep the combustion process smooth and safe.

They also include lambda sensors that effectively manage the internal temperature of the boiler. These sensors keep the temperature at a controlled level, preventing explosions and internal damage.

Additionally, these boilers feature automatic ash removal systems that prevent ash accumulation in the furnace. This accumulation can cause internal damage due to excessive heating.

Safety Tips:

- Always follow the boiler’s instructions and never exceed working pressure.

- Check safety valves regularly.

- Always wear masks and gloves when operating the boiler.

- Regular cleaning of boiler tubes prevents clogging and corrosion.

- Frequently check for steam or fuel leaks for timely repairs.

2. Environmentally Friendly

Today, industries have become a major source of environmental pollution. This is why industrialists must look for options that pollute less and are environmentally friendly. Industrial wood steam boilers use biomass fuel in the form of wood.

Wood waste is a super eco-friendly heat-producing fuel as it can reduce greenhouse gas emissions by up to 90%. Moreover, wood biomass boilers consume less electricity compared to other coal or gas-fired boilers.

In terms of carbon neutrality, industrial wood steam boilers are the best choice. Carbon neutrality refers to how efficiently a boiler absorbs greenhouse gases that might pollute the environment. Wood-fired boilers are carbon neutral as they use wood as their primary fuel source.

Besides these environmental benefits, wood steam boilers also emit the least amount of CO2 in the environment compared to lignite and natural gas. They emit only 9 to 18 grams of CO2, while lignite emits 9 times more.

3. Easy to Operate and Use

Industrial wood steam boilers are simple boilers that are easy to operate. Once set up by professionals, they require minimal attention.

Additionally, their safety control systems are highly efficient as they maintain internal temperature and automatically control ash removal. Moreover, there’s no risk of flame flare-ups or ash backfiring. These boilers also come in different ranges, making them suitable for performing various applications without any extra effort.

Wood-fired boilers use wood fuel that can be used in all seasons and weather conditions. This means you don’t have to trouble yourself to meet your fuel needs. This fuel is not only easily available but also easy to measure and manage for efficient heat production.

Another major advantage of choosing industrial wood steam boilers is their self-cleaning system, which further adds to ease of operation.

4. Economical Boiler

This might be the number one reason to replace your old boiler with an industrial wood steam boiler. In many cases, wood-fired steam boilers can save you a lot. First, the fuel they consume is much cheaper than other fuels like oil or gas. Moreover, the amount of fuel consumed is less as wood waste comes in bulk and burns for longer durations.

Second, their purchase price is also reasonable and affordable. Their prices start from $9,000 and vary by model. Some companies also offer free operation and maintenance for a considerable period, saving you money.

Furthermore, industrial wood boilers cost 30% less than other boilers. They save your budget on manual labor, operation and maintenance costs, and cleaning services. They can also reduce your heating expenses by up to 50%.

5. Highest Quality Steam Production

As promised earlier, this is the most crucial reason to purchase an industrial wood steam boiler. Apart from cost, the biggest concern for any industry is the steam produced by the boiler. Since wood-fired boilers use biomass fuel, they produce naturally pure steam. This steam is also of high quality, resulting in better industry operations.

This highest quality steam is highly efficient, with thermal efficiency up to 95%. This means your boiler will consume less fuel and save your hard-earned money. What more could you wish for? Low cost and more energy savings.

System Diagram

- Steam Pipeline

- Water Pipeline

- Water Return Pipeline

Equipment Names:

- Boiler

- Cooler

- Water Scheme

- Water Task

- Water Separating Headers

- Feed Water Pump

- Decomposition Pump

- Chimney

- Energy-Setting Pump

- Conversion

- Decoveryer

Conclusion

No matter what industry you operate, industrial wood-fired boilers are your best choice. They have all the super qualities you consider when choosing an industrial boiler. This includes your safety, 40% to 50% lower operating costs. Moreover, they’re easy to operate and maintain, reducing manpower needs.

The best part is they’re environmentally friendly, reducing greenhouse gas emissions while providing you with high-quality steam production. So now that you’ve considered purchasing an industrial wood steam boiler, you can contact us to find the right one for your industry.

About Boiler Philippines

Boiler Philippines is a top steam boiler manufacturer. We have about 40 years of experience in providing you with the best steam boiler systems. We guarantee 100% factory prices for steam boilers. Our oil/gas boilers achieve 98% efficiency, while coal/biomass boilers achieve 85% efficiency. Our team is committed to providing you with the most economical steam boiler solutions.

Our Industrial Boilers:

- Steam Boilers

- Coal-Fired Boilers

- Biomass Steam Boilers

- Thermal Oil Boilers

- Vertical Boilers

Chain Grate Stokers

- Chain Grate Stoker

- Reciprocating Grate

- Grate Bars

For more information, visit us at: www.boiler.ph