Chain Grate Stoker Boilers

Chain grate stoker boilers provide a cost-effective solution for both large industries and small industrial users. These modern boilers use a grate stoking system that allows for complete combustion and lower emissions.

Applications

- Power plants

- Chemical industry

- Heating systems

- Water supply systems

- Air conditioning system heating

Key Features

- Uses less fuel compared to other boiler types

- Reduced carbon footprint

- Produces less ash

- Lower greenhouse gas emissions

- Materials can be customized (typically steel plates or alloy steel plates)

Travelling Grate (Pinhole Grate) Boilers

Pinhole grate boilers feature a fixed grate designed for burning low-ash fuels. These high-quality, robust and cost-effective boilers are particularly suitable for biomass fuels.

Technical Specifications

- Available in sizes from 30kW to 1MW

- Compact design allows installation anywhere with fuel access

- Suitable for commercial and industrial applications

Construction Features

- Made from high-strength steel plates with small surface holes

- Ensures complete combustion while preventing flame penetration

- Ideal for high-temperature, high-pressure steam boilers

- Widely used in metallurgy, chemical industries, and coal gasification

Advanced Design Elements

- All-steel construction with stainless steel combustion chambers

- Large diameter fire tubes for rapid heat transfer

- Efficient circulating fluidized bed combustion system

- Can accept air temperatures up to 250°C

- Capable of burning high-moisture bagasse

- Over-fire air system ensures complete combustion

Grate Systems Explained

What is a Boiler Grate?

The grate is part of a steam boiler that supports the fire and allows air circulation. Typically made of metal, the grate helps maintain proper combustion by allowing airflow through the firebox. Without this airflow, there wouldn’t be enough oxygen for complete combustion.

Types of Stokers

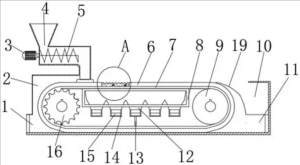

- Chain grate stoker/travelling grate stoker: Coal is fed onto one end of a moving steel chain grate. As the grate rolls along the length of the boiler furnace, the coal burns and drops off as ash at the end.

- Spreader stoker: Classified by how fuel is fed into the furnace and the grate type.

- Underfeed stoker: Fuel is placed in a large hopper at the front of the furnace, with coal conveyed to a horizontal trough where it mixes with air.