Introduction

These mechanical systems are essential as they reduce nearly 97% of total air pollutant emissions. These boilers can generate electricity with 34% to 37% net thermal cycle efficiency, producing greater heat and achieving over 42% efficiency without harming the planet.

Pulverized Coal Fired Boiler Design and Components

These high numbers demonstrate that pulverized coal fired boilers dominate electricity generation in power plants. They provide better economic and ecological approaches by reducing fuel consumption and pollution.

An industrial or utility boiler that burns pulverized coal blown into a firebox is called a pulverized coal boiler. “Pulverized coal” refers to coal extracted from sedimentary rock broken down into small particles, typically black and producing thermal energy.

The boiler’s furnace or base area contains burners and the combustion system. In traditional combustion boilers, this is where combustion occurs.

Additionally, the convection section houses the convection heat transfer surfaces. Typically, the boiler’s membrane walls serve as evaporators, and the convection section contains heat exchanger components.

In standard boiler designs, heat exchangers are arranged according to flue gas flow as follows:

- Superheater 2 (acts as a hanging superheater)

- Superheater 4

- Reheater 2

- Superheater 3

- Reheater 1

- Economizer 2

- Economizer 1

Modern boiler design elements include dry ash removal, super water-cooled furnaces, and regulated ventilation settings. They also feature horizontal and vertical convection passages to reduce initial investment costs.

Technical Specifications

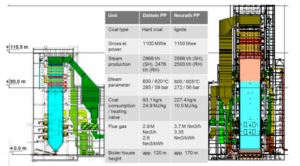

| Unit | Dattain PP | Neurath PP |

|---|---|---|

| Coal type | Hard coal | Lignite |

| Gross electrical power | 1100 MWe | 1100 MWe |

| Steam production | 2868 t/h (SH), 2476 t/h (RH) | |

| Steam parameter | 600 / 620 °C 285 / 59 bar | |

| Coal consumption / heating value | 93.1 kg/s 24.9 MJ/kg | |

| Flue gas | 2.9 M Nm3/h 2.6 Nm3/kWh | |

| Boiler house height | approx. 120 m | approx. 170 m |

Reheat and superheat layers come in both horizontal and vertical configurations. While the horizontal and vertical convection passage enclosures are typically steam-cooled, natural circulation cools the furnace wall.

Temperature regulation is crucial in pulverized coal fired boilers. A spray temperature controls the superheat temperature, and gas proportioning dampers at the reheater and economizer exits regulate the reheat temperature.

A reheat spray attemperator is used during transient load and boiler breakdown conditions, with spray volumes minimized for optimal engine efficiency.

Rotating filters enhance coal fineness while consuming less fuel to ensure ideal performance, increasing engine efficiency. Adjustable grinding unit loading systems enable optimal mill turndown without excessive vibration.

Ceramic components and coatings increase service duration, while rotating air entrance “throats” prevent pressure loss.

Role in Electricity Production

An EGU (Electric Generating Unit) is a static boiler or combustion turbine that drives a generator to produce electricity. EGUs have three main boiler types for utilizing and burning coal, with pulverized coal (PC) units being the most effective.

In these boilers, coal is crushed into small particles via a pulverizer. This powdered coal is then burned in a burner. Most coal EGU technologies are PC units, comprising about two-thirds of units currently used for electricity production.

Several coal EGU components generate electricity in power plants or other industries. These components don’t require huge, tailored parts or special metals to handle specific high steam temperatures and pressures.

Using such components benefits the overall economy as they are readily available and durable.

Role of Coal Pulverizers

Coal pulverizers are primarily made of steel and steel parts, standing approximately 30 feet tall. Several autonomous pulverizers are typically installed for an EGU to meet firing and performance criteria.

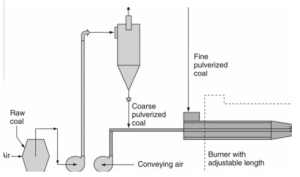

The process begins with coal being placed into a pulverizer for PC units, where it’s ground into a fine powder to aid combustion. The coal is mechanically crushed to appropriate fineness, with larger particles reground and moisture removed before burning.

After grinding, the coal is pushed through a burner. As the mixture reaches the boiler, the burner ignites the coal with controlled airflow. Each pulverizer typically has four to eight burners, with at least four pulverizers feeding a larger boiler.

Lowering combustion temperatures and oxygen concentration during initial coal burning stages can significantly reduce smog-forming NOx production.

Finally, the mixture is transported to a coal-fired steam boiler. While boilers burn various fuels, those designed for power plants are massive, integrated systems built with specialized materials and machinery.

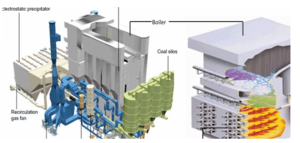

Pollution Control

Plant owners can shift to lower-sulfur coal to reduce SO2 emissions and meet environmental standards. Another pollution reduction method is using SCR (Selective Catalytic Reduction) technology.

SCR is part of the pollution-control system in these boilers, located in the exhaust. The SCR or SNCR system injects ammonia into the flue gas to eliminate NOx.

After pollutants are removed, residual flue gases are released into the atmosphere through tall smokestacks or chimneys (hundreds of feet high), built from reinforced concrete and lined with specialized materials to withstand corrosive conditions and high temperatures.

Cost Estimation

Estimated cost distribution for pulverized coal fired boilers in power plants:

| Component | Percentage of Costs |

|---|---|

| Coal and sorbent handling, preparation, and feeding | 6% |

| Feedwater systems | 10% |

| Boiler and NOx controls | 35% |

| Flue-gas cleanup | 18% |

| Ductwork and smokestack | 4% |

| Steam piping | 5% |

| Cooling water system | 3% |

| Waste-handling system | 1% |

| Accessory electric plant and controls | 6% |

| Site improvements, buildings, and structures | 1% |

Advanced Trends and Performance Goals

Globally, initiatives are underway to develop cutting-edge pulverized coal fired boiler systems that meet future power production demands in economically and ecologically acceptable ways.

Key aspects include increasing thermal efficiency, improving sustainability impact, growing prevalence, controlling initial capital costs, and managing overall power costs.

A slight difference in operating cost can achieve greater thermal efficiency, offering various benefits. Over 70% of a fossil fuel-fired power plant’s operating expenses relate to fuel consumption.

Regulating this can allow efficiency improvements to offset additional investments while giving plants a strategic advantage in the global power market.

Reduced fuel usage per kilowatt-hour generated immediately lowers production of primary air pollutants (SO2, NOx, and particulates), making efficiency improvements one of the most cost-effective ways to reduce CO2 emissions.

While exact performance indicators vary, common targets include:

- Thermal effectiveness of at least 42% (higher heating value basis), with long-term goals reaching 50% HHV

- Pollutant emission levels:

- SO2 < 0.1-0.2 lb/106 Btu (120-250 mg/Nm3)

- NOx < 0.1 lb/106 Btu (120 mg/Nm3)

- Particles 0.015 to 0.030 lb/106 Btu (20-40 mg/Nm3)

- Water discharge ~ 0

- Solid waste = minimum

- Minimal change or decrease in electricity cost

Conclusion

Pulverized coal fired boilers are indeed an ideal solution for power plants. Designed to withstand extreme temperatures while significantly reducing pollution and emissions, they achieve optimal performance.

These systems benefit not just ecology but also the economy. When resources are well-utilized with reduced waste, cost savings and higher industry annual revenue can be expected.