Your Next Industrial Condensing Gas Boiler | A Simple 2025 Guide

Have you been considering an industrial condensing gas boiler but can’t make up your mind? We’ve got you covered! Industrial condensing steam boilers are highly popular for their top-tier efficiency, significantly reducing energy costs and carbon footprints. However, there’s a lot to understand before making a decision.

In this article, you’ll find detailed information about industrial condensing gas boilers, including how they work, their efficiency, lifespan, and more. You’ll also learn about the best industrial condensing gas boilers to help you make an informed choice. Let’s dive in!

How Condensing Gas Boilers Work

The primary question is: How do industrial condensing gas boilers work, and how do you choose a condensing steam boiler? Condensing boilers utilize condensation technology to maximize heat efficiency. They burn fuel to generate heat, which is then transferred to radiators to provide system warmth.

Additionally, they produce fewer carbon monoxide and nitrogen oxide emissions, reducing factory pollution.

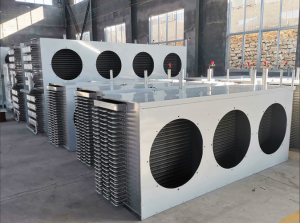

The standout feature of condensing boilers is their ability to capture heat from exhaust gases produced during combustion. They have an extended heat exchange surface, converting more heat from the burner into usable energy.

Once water circulates in the central system, this energy is reused to heat water, reducing the energy required to start the heating process. This demonstrates how industrial condensing gas boilers achieve higher efficiency while using less energy for the same output.

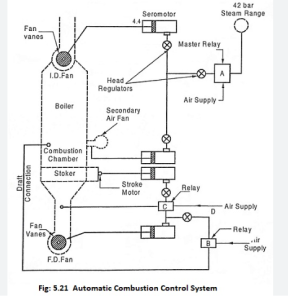

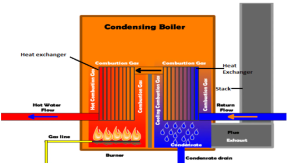

Condensing Boiler Diagram

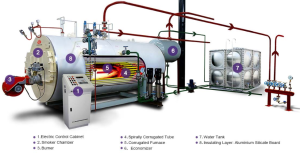

The diagram below illustrates the components of a typical condensing boiler and their functions. The heat exchanger heats water while cooling exhaust gases from fuel combustion.

Outdoor pipes expel these gases (also called flue gases). The latent heat energy in the gases is released during cooling via condensation. The boiler then uses this thermal energy to continue powering the central heating system.

Pros and Cons of Condensing Boilers

Industrial condensing gas boilers offer advantages like reduced carbon footprints and higher efficiency, but they also have drawbacks. Let’s compare their pros and cons to determine if they’re worth the investment.

Advantages of Condensing Boilers

- Latent Heat Recovery

This improves thermal efficiency, the primary advantage of condensing boilers. The moisture content in boiler fuel is around 50%. During condensation, the heat exchanger recovers latent heat from this moisture, achieving efficiencies exceeding 100% compared to the fuel’s lower calorific value. - Reduced Emissions

Condensing boilers use flue gas condensers to lower emissions. Condensation forms a layer that traps large particles like sulfates and chlorides, reducing harmful emissions, including CO₂ and nitrogen oxides. Installing a condensing boiler can cut carbon footprints by up to 1,200 kg. - Lower Energy Costs

To prevent heat loss, condensing boilers preheat cold water before it enters the system. This maximizes efficiency, allowing the boiler to use less fuel and reduce costs compared to other industrial gas boilers. - Space Savings

Condensing boilers don’t require hot water tanks, making them easier to install in tight spaces—ideal for limited boiler rooms.

Disadvantages of Condensing Boilers

- Higher Maintenance Costs

Condensing boilers are more complex and require professionals with gas safety certifications, increasing costs. Non-condensing boilers are cheaper to repair short-term, but condensing boilers save money long-term. - Corrosion Risks

Combustion byproducts can cause corrosion, especially under mechanical strain, leading to cracks in low-temperature steel heat exchangers. Using corrosion-resistant materials, careful installation, and advanced controls can mitigate this. - Complexity

In cold weather, external pipes may freeze, causing the boiler to stop working. Acidic condensate can also cause corrosion, but proper maintenance can minimize these risks.

Condensing Boiler vs. Combi Boiler: Are They the Same?

A common question is: Are condensing boilers and combi boilers the same? The short answer is no. Condensing boilers refer to the technology used to improve efficiency, while combi (or combination) boilers don’t require storage tanks.

Interestingly, a condensing boiler is required for a combi boiler installation, but not all condensing boilers are combi boilers—they can also be conventional or system boilers.

Condensing vs. Non-Condensing Boilers

Industrial condensing gas boilers are far more efficient than non-condensing models. Modern condensing boilers achieve efficiencies of 90% or higher, while non-condensing boilers max out at 70–80%.

Condensing boilers use flue gas recovery systems to preheat incoming cold water with waste heat, reducing fuel consumption for the same output. This makes them not only more efficient but also more eco-friendly.

| Feature | Condensing Boiler | Non-Condensing Boiler |

|---|---|---|

| Annual CO₂ Emissions | 5.2 tons | 7.95 tons |

| Cost Efficiency | Higher upfront cost, long-term savings | Lower upfront cost, less efficient long-term |

| Combustion Temperature | 50–60°C | 120–180°C |

Industrial Condensing Gas Boiler Efficiency

Condensing boiler efficiency is measured by Annual Fuel Utilization Efficiency (AFUE). A 90% AFUE means 10% energy loss, with 90% converted into usable heat. Higher AFUE ratings mean greater savings.

On average, industrial condensing gas boilers are 12% more efficient than non-condensing models. They recover 30% of heat that non-condensing boilers waste, boosting efficiency to 99% with flue gas heat recovery systems.

Do You Need a Hot Water Tank with a Condensing Boiler?

In short, no—condensing boilers don’t require hot water tanks. However, the answer depends on the boiler type:

- Combi boilers don’t need tanks.

- System or heat-only boilers may require them.

Combi boilers heat water on demand, while system or heat-only boilers store hot water in tanks.

Is Installing an Industrial Condensing Gas Boiler Complicated?

Installation isn’t overly complex. The main difference from non-condensing boilers is the need for condensate drainage. A skilled installer can easily position a drain and install a plastic overflow pipe.

Best Condensing Boilers

Pricing

- 4 tons/hour steam output: $500–$7,000

- 60 tons/hour steam output: $6,000–$30,000

- Higher-capacity models: Up to $100,000+

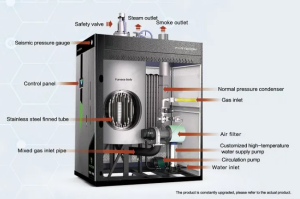

Top Industrial Condensing Boiler Specifications

Here’s a standout condensing steam boiler:

- Horizontal integrated design saves space.

- Larger chamber heats faster with less energy.

- Threaded flue pipes and corrugated furnace threads enhance heat transfer and fuel efficiency.

- Safety features like explosion-proof doors ensure continuous safety.

Final Verdict

Industrial condensing gas boilers are in high demand due to their efficiency and reduced carbon footprint. They also lower energy costs and save space. However, drawbacks like corrosion exist.

The good news? These can be mitigated with careful purchasing and timely maintenance. For the best deals, buy from reputable suppliers like Boiler Philippines, offering affordable prices and post-installation support.

About Boiler Philippines

We are a leading steam boiler manufacturer with decades of experience in delivering top-tier boiler systems. Our oil/gas boilers achieve 98% efficiency, while coal/biomass models reach 85%. We’re committed to providing the most economical steam boiler solutions.

Our Products

- Steam boilers

- Coal-fired boilers

- Biomass steam boilers

- Thermal oil boilers

- Vertical boilers

For inquiries, visit www.boiler.ph.

z

z