Steam Boilers in the Paper Manufacturing Industry

Steam boilers play a vital role in paper manufacturing, serving as the heart of thermal energy supply for production processes. These systems not only ensure stable heat delivery but also significantly impact paper quality and production efficiency. This article explores the applications, optimization strategies, and environmental technologies of steam boilers in paper manufacturing.

The Critical Role of Steam Boilers

The paper industry has enormous energy demands, and steam boilers meet these requirements by providing powerful heat output for various production stages:

- Raw material pretreatment

- Pulping processes

- Bleaching operations

- Paper drying and forming

- Calendering and finishing

Steam application accelerates production timelines while enhancing final product quality, making boilers indispensable in modern paper manufacturing.

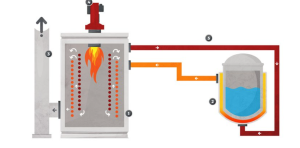

Paper Production Line Overview

Paper manufacturing involves complex processes where steam serves essential functions:

Key Production Stages:

Raw Material Preparation: Steam adjusts material moisture for optimal processing

Pulping: Steam heats and softens fibers for mechanical/chemical treatment

Bleaching: Steam activates bleaching agents for improved efficiency

Wire Section: Steam controls humidity for proper sheet formation

Drying: Steam-heated air rapidly removes moisture

Calendering: Steam heats rollers to enhance surface smoothness

Precise steam temperature and humidity control directly affect paper quality, strength, and appearance throughout these processes.

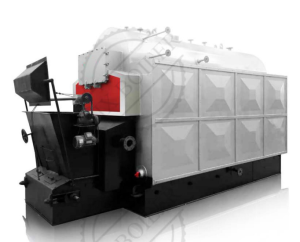

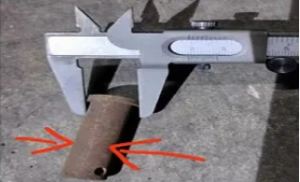

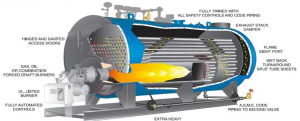

Recommended Boiler Model: SZL Series

Boiler Philippines recommends the SZL series steam boiler for paper manufacturing applications, featuring:

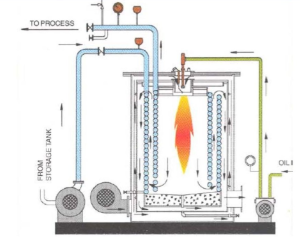

- Double-drum longitudinal design: Ensures continuous, uniform steam generation

- Chain grate stoker: Promotes even fuel distribution and complete combustion

- Water-cooled walls: Protects furnace while absorbing thermal energy

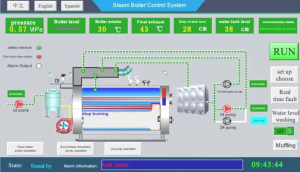

- Automated control system: Precisely regulates fuel/air ratios for safe operation

These features combine to deliver high thermal efficiency ideal for paper production needs.

Boiler Operation Optimization

Enhance paper manufacturing efficiency through these boiler optimization strategies:

Performance Improvements:

- Load management: Match output to production demands

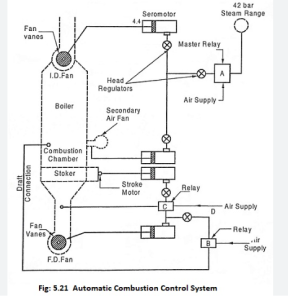

- Combustion optimization: Fine-tune parameters for maximum efficiency

- Automated controls: Maintain precise steam pressure/temperature

- Preventive maintenance: Regular inspections and component servicing

Production Line Integration

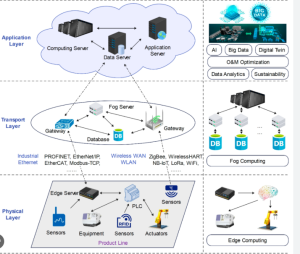

Modern integration solutions connect boilers seamlessly with paper manufacturing:

- Real-time data exchange: Automatic boiler adjustments based on production needs

- Energy management: Comprehensive monitoring for optimal consumption

- Environmental control: Precise steam conditioning for process stability

Environmental Protection Measures

Boiler Philippines implements sustainable technologies for greener operations

Eco-Friendly Solutions:

- Emission controls: Advanced desulfurization and denitrification systems

- Waste heat recovery: Utilizing flue gas energy for preheating

- Clean fuels: Biomass alternatives to reduce fossil fuel dependence

Conclusion

As the core of paper manufacturing systems, steam boilers enable both production efficiency and quality control when properly optimized. By implementing advanced control systems and environmental technologies, Boiler Philippines helps paper manufacturers achieve sustainable operations without compromising performance.

About Us

Boiler Philippines is a leading steam boiler manufacturer with 40 years of industry experience, committed to delivering cost-effective thermal solutions.

Contact Information

Email: [email protected]

Address: Manila, Philippines

Visit us at: http://www.boiler.ph