A Complete Guide to Oil-Fired Hot Water Boilers

Hot water is a vital need for industries and homes, especially in regions with colder climates. Bulk hot water production is only feasible with an oil-fired hot water boiler system.

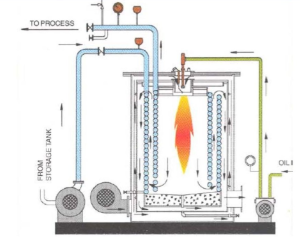

Hot Water boiler Oil Fired System Drawing

What Is an Oil-Fired Hot Water Boiler System?

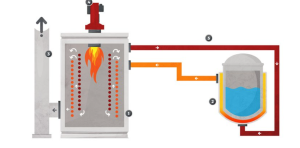

An industrial hot water boiler is a complex network of vessels enclosed in a metal container. It uses heat energy from fuel combustion to raise water temperature, which is then transported through pipes for industrial use.

Design of an Oil-Fired Hot Water Boiler

Unlike commercial systems, industrial boilers do not boil water but heat it to 220°F (beyond the standard boiling point of 212°F) due to increased internal pressure.

Key Design Features:

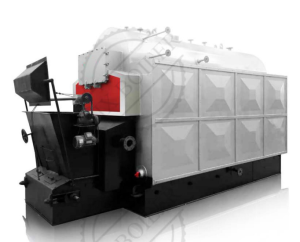

- Compact and durable: Made from anti-corrosive metals like stainless steel.

- Lightweight insulation: Aluminum silicate fiber lining for temperature and pressure resistance.

- Shape options: Circular, vertical, or horizontal designs.

Components of an Oil-Fired Hot Water Boiler

Every boiler includes these core parts:

- Burner: Combusts fuel (oil, gas, or solid) to generate heat.

- Heat Exchanger: Transfers heat from combustion to water.

- Combustion Chamber: Space where fuel burns continuously.

- Control Systems: Automation tools for monitoring temperature, pressure, and alarms.

Accessory Parts (Optional):

- Economizer

- Circulation pump

- Aquastat

- Feedwater heater

- Condenser

Types of Industrial Hot Water Boilers

1. Gas-Fired Boilers

- Fuels: Natural gas, LPG, propane, or butane.

- Most efficient but costly.

2. Oil-Fired Boilers

- Fuels: Light oil, heavy oil, kerosene, red diesel.

- Ideal where piped gas is unavailable.

3. Solid-Fuel Boilers

- Fuels: Wood, coal, agricultural waste.

- Lower efficiency but cost-effective.

4. Electric Boilers

- 98% efficiency; requires stable power supply.

5. Vacuum Boilers

- Operates under negative pressure for safety.

- Energy-efficient and versatile for varying temperature needs.

How Does an Oil-Fired Hot Water Boiler Work?

- Fuel Intake: Oil is fed into the combustion chamber.

- Combustion: Heat is generated and transferred via the heat exchanger.

- Water Heating: Water circulates through tubes, absorbing heat.

- Distribution: Hot water is pumped to industrial systems.

Advantages of Oil-Fired Hot Water Boilers

- Safety: Stainless steel construction and pressure-resistant design.

- High Efficiency: Up to 98% with economizers/condensers.

- Automation: Smart controls for temperature regulation and leak detection.

Safety Precautions

- Wear protective gear.

- Regularly check fuel/water levels and leaks.

- Never leave the boiler unattended.

Maintenance Steps

- Inspect: Fuel lines, water supply, and heat surfaces.

- Revise: Professional check every 2 years.

- Clean: Remove residue and blockages.

Cost Range

- Standard boilers: $9,000–$80,000 (capacity-dependent).

- 5-ton boilers: $55,000–$98,000.

Why Choose Boiler Philippines?

With 40+ years of expertise, we provide:

- Durable, lightweight boilers with aluminum silicate insulation.

- Custom temperature control (10°C–90°C).

- Microcomputerized systems for precision.

Contact us today for a tailored solution!