While their advantages include low fuel quality requirements and automatic fire management, significant drawbacks exist. During regular industrial boiler inspections, we frequently encounter severe burn-through and deformation of horizontal grates, with some requiring replacement after just a few months of operation. These issues directly impact production efficiency.

Case Study: SZL10-1.0-AII Industrial Steam Boiler

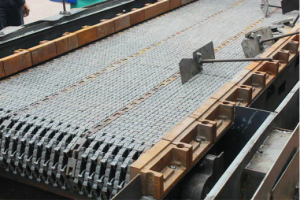

This boiler plant was manufactured in December 2019 and began operation in December 2021. All pre-commissioning instrument checks indicated good furnace condition and normal stoker operation. After two years of operation, significant grate problems emerged.

Extensive burn deformation severely affected production, with the shortest replacement interval being just three months. Upon inspection, removed grate fragments showed severe corrosion, with some grate bars reduced to just 2/3 or less of their original length.

Factors Affecting Chain Grate Stoker Burnout

1. Fuel Selection

Chain grate stokers are suitable for medium-low volatile bituminous coal, inferior coal, lignite, and biomass fuels with low calorific value (below 5000 kcal/kg).

The coal used in this case had a calorific value of about 5500 kcal/kg, which is too high for horizontal chain grate stokers. Certain coals like coking coal, gas coal, lean coal, and lignite tend to cake easily, exacerbating grate problems.

2. Chain Grate Stoker Design

The design significantly impacts fuel combustion through several aspects:

- Grate bar material: The RQTAI5Si heat-resistant cast iron specified wasn’t used – instead IT150 material was substituted, which cannot withstand the maximum working temperature of 900°C.

- Grate bar size: While geometric dimensions and overlapping methods met specifications, material issues remained problematic.

- Ventilation: Proper spacing between grate bars and moderate coal particle size are crucial to prevent carbon particle blockage that hinders cooling.

3. Grate Bar Manufacturing Process

While current casting technology achieves good yields with smooth surfaces free of defects like blowholes, material selection remains critical for longevity.

4. Boiler Operation Management

Several operational factors contribute to grate burnout:

- Improper coal bed thickness and stoker travel speed

- Failure to promptly remove fine ash accumulation in air chambers

- Poor grate ventilation due to excessive coal bed density

- Inadequate ventilation in high-temperature zones

- Excessive furnace positive pressure or strong arch reflection

- Improper shutdown procedures allowing coal to burn on the grate

Root Causes of Grate Burnout

Three primary factors were identified in this case:

- Incorrect grate bar material selection (failure to use RQTSi5 material in main combustion zones)

- Long-term positive pressure combustion affecting primary air and grate cooling

- Excessive temperature at the coal-grate contact point due to poor cooling

These issues created a vicious cycle that significantly shortened grate lifespan and caused unnecessary economic losses.

Recommended Solutions

- Replace main combustion zone grate bars with RQTSi5 material to improve heat resistance

- Use bituminous coal with lower calorific value (~4000 kcal/kg)

- Mix coal with slag or use coal blends to improve combustion and maintain negative pressure operation

- Ensure proper grate cooling through optimal coal bed thickness and stoker travel speed

Implementing these measures will extend grate lifespan and ensure safe, stable boiler operation.