What Are Industrial Boilers?

Industrial boilers are pressurized vessels used to generate steam for various industrial applications. Through the creation of clean, efficient energy, industrial boilers from Boiler Philippines help customers increase revenue.

Types of Industrial Boilers

There are several different types of industrial boilers, each with its own advantages and disadvantages.

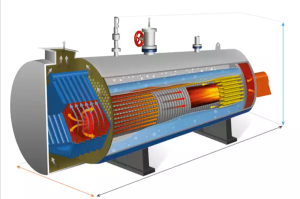

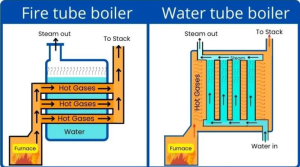

Fire Tube Boilers

The most common type of industrial boiler is the fire tube boiler, which consists of a series of tubes filled with water. The water is heated by a series of burning fuels, and the resulting steam is used to power various industrial applications.

Fire tube boilers are very large and require a significant amount of fuel to operate.

Water Tube Boilers

Another type of industrial boiler is the water tube boiler, which consists of a series of tubes filled with water. The water is heated by a series of burners, and the resulting steam is used to power various industrial applications.

Water tube boilers are much smaller than fire tube boilers and operate more efficiently.

10 Different Industries That Use Industrial Boilers

1. Food Industry Boilers

Water or other fluids are heated by our industrial boilers. The liquid doesn’t need to boil. Various heating applications such as water heating, central heating, boiler-based power generation, cooking, and sanitation can be performed by the heated or vaporized fluid exiting the boiler.

Food industry boilers can be used for drying, sterilizing, curing, distilling, and sterilizing. In fact, thermal oil boilers are recommended as a better choice for the food industry.

2. Rice Mill Steam Boilers

The rice mill steam boiler is a critical piece of equipment in rice processing. It provides the steam needed for the harsh environment of the rice mill while also providing the power to drive the rice milling equipment.

The rice mill steam boiler is used to remove the husk from rice. The rice boiler process feeds the rice into the husk bucket, separating it from the husk.

3. Brewery Steam Boilers

It’s essential to understand how a steam boiler works in any brewery. It produces steam by heating water. The brewery’s steam boiler produces steam by heating water. Afterwards, the steam is used to power brewing equipment such as fire kettles and mash tuns.

4. Sugar Industry Boilers

The boilers used in the sugar industry are essential equipment in sugar mills as they are responsible for generating steam to power the mill’s machinery. They help in crystallizing and drying sugar. Most boilers in the sugar industry use bagasse, coal, and biomass as fuel.

5. Textile Industry Steam Boilers

The textile industry uses steam boilers to convert water into steam using thermal energy. The steam is then used to run large turbines that generate electricity. Steam boilers are essential equipment in the textile industry as they help generate the steam that powers the turbines.

6. Milk Processing Steam Boilers

In milk processing plants, steam boilers are very commonly used. To kill microorganisms, milk is heated to high temperatures and then cooled. The milk is then processed into cheese, butter, yogurt, and other items.

7. Pharmaceutical Industry Boilers

For pharmaceutical plants, it’s very important to have boilers for heating. If steam boilers are used for drying, sterilization, or purification of drugs, they must be very precise. This means they must be able to maintain temperature very stable.

8. Distillery Incineration Boilers

Incineration boilers are commonly used in distilleries as a way to process waste. The incineration process helps to sanitize the waste, and the heat produced can be used to generate steam or hot water.

9. Oil and Gas Industry Boilers

Boilers have multiple uses in the oil and gas industry, including powering refinery operations and providing energy for offshore rigs. In addition to generating steam, boilers can also be used to produce hot water for space heating, domestic hot water, or process heating.

10. Distillery Steam Boilers

In the distillation process, steam is used to heat the wort, which breaks down the sugars and creates alcohol. The steam boiler also provides steam to the stills for further distillation of the alcohol.