As an industrial professional, you know the market is flooded with thousands of high-efficiency boilers. However, many are either too expensive or emit harmful gases. This comprehensive guide explores why wood-fired boiler systems present an affordable, efficient alternative for industrial applications.

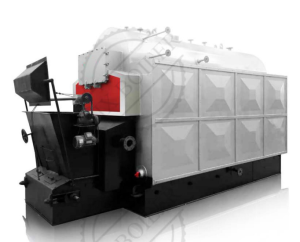

System Overview

Key Components:

Wood Boiler Systems: Definition and Operation

A wood-fired boiler system is a heating device that converts renewable wood fuel into thermal energy. Utilizing advanced combustion technology and control systems, it efficiently transfers heat from burning wood to water. Key components include the combustion chamber, chimney, control furnace, and automated systems that ensure both high efficiency and operational safety.

How Wood Boiler Systems Work

The process begins by loading wood into the combustion chamber and igniting it. The generated heat transfers to water through a heat exchanger. This heated water circulates through pipes to radiators and heating plates, then returns for reuse after cooling. For optimal performance, water must be free of impurities like metals. The system typically provides heat ranging from 1300°C to 1900°C.

System Structure

1. Combustion Chamber

The heart of the system where fuel (wood, coal, rice husks, etc.) burns. Design flexibility allows customization for different fuel types and operational requirements.

2. Radiation Heat Collector

Constructed from cast steel pipes to capture and utilize heat emitted during furnace operation.

3. Ash Handling System

Integrated screw mechanisms ensure efficient ash and slag removal, maximizing energy efficiency.

4. Furnace Body

Features multiple pass systems (1-3) with various pipe configurations managing steam valves, safety components, and control signals.

5. Dust Removal System

Essential for environmental protection and energy conservation by removing particulate matter.

6. Dust Suppression Tank

Uses water sprays to neutralize collected dust, ensuring cleaner emissions.

Types of Wood Boiler Systems

Log Boilers

- Most affordable option

- Compact and user-friendly design

- Up to 85% efficiency

Pellet Boilers

- Highest efficiency (up to 95%)

- Quiet operation with automatic feeding

- Longest lifespan among wood boilers

Chip Boilers

- Up to 90% efficiency

- Convenient silo storage system

- Similar functionality to pellet boilers

Key Technologies

Push-Fire Technology

Adaptable to various wood shapes, sizes, and moisture levels, making it ideal for handling diverse fuel qualities.

Fluidized Bed Technology with Smoke Circulation

Offers exceptional flexibility with temperature regulation capabilities and stable operation across different fuel types.

Fuel Selection Guide

Hardwoods (Recommended)

Oak, beech, ash, walnut, and fruit trees provide slow, consistent burns ideal for industrial applications.

Softwoods

Fir, spruce, and pine offer quick heat but require careful storage and management due to faster degradation.

Important Note on Wood Moisture

Never burn wet (“green”) wood. It reduces energy output by 50%, increases environmental impact, and accelerates equipment deterioration. Always use properly seasoned wood for optimal performance.

Four-Step Operational Guide

1. Professional Installation

Proper sizing and expert installation ensure optimal system performance from the start.

2. Fuel Preparation

Use dry, properly sized wood. Consult experts for storage best practices to maximize fuel efficiency.

3. Daily Operation

Monitor boiler at least twice daily. Refuel as needed based on thermostat signals and water circulation patterns.

4. Maintenance

Critical for longevity and efficiency:

- Regular ash removal with provided tools

- Heat exchanger cleaning (simplified in modern designs)

- Annual professional inspections and adjustments

Efficiency Factors

Wood boilers can achieve up to 90% efficiency when:

- Using quality hardwoods

- Maintaining proper moisture content (below 20%)

- Operating at optimal temperatures

- Following regular maintenance schedules

- Implementing automated feeding systems

System Longevity

With proper care, wood boiler systems can last up to 20 years. Key preservation practices include:

- Exclusive use of seasoned dry wood

- Regular firebox cleaning to prevent soot buildup

- Periodic inspections for leaks or cracks

- Annual professional servicing

Comparative Analysis: Wood vs. Electric Boilers

Wood Boiler Advantages:

- Lower operational costs

- Renewable fuel source

- Higher energy independence

Electric Boiler Advantages:

- Cleaner operation

- Advanced control systems

- Simpler safety profile

Conclusion

Wood-fired boiler systems offer industries an efficient, eco-friendly, and cost-effective heating solution. Achieving optimal performance requires proper fuel selection, regular maintenance, and professional installation. When selecting equipment, always choose reputable manufacturers to ensure quality and reliability.

For premium wood boiler systems backed by decades of engineering expertise, trust Boiler Philippines. Our solutions combine exceptional efficiency with unmatched reliability to meet your industrial heating needs.

Learn more at www.boiler.ph