With the development of the times, many people believe that coal-fired steam boilers will eventually be replaced by new energy sources and gas. However, this is not the case. Currently, new energy sources face instability in terms of access, efficiency, and cost, and a complete replacement of coal will take some time. Especially since gas remains an unstable heat source, coal-fired boilers will continue to be a major player in the market for the foreseeable future.

Why We Recommend Choosing Coal-Fired Boilers

- Stable Coal Supply: In the energy sector, coal holds a leading position. As a fossil fuel, it has a certain storage base, ensuring a stable, convenient, and continuous supply with high reliability.

- Higher Overall Efficiency: Compared to natural gas, coal remains relatively low in cost. The construction of natural gas pipelines is expensive and carries potential risks. For example, two years ago, China promoted the use of natural gas boilers, but many had to cease operations due to natural gas shortages. Coal-fired boilers can coexist with biomass boilers, helping enterprises achieve good production efficiency. They are highly favored in the industrial and power sectors.

- Mature and Stable Technology: The development of coal-fired boilers has spanned over half a century, undergoing multiple technological improvements and innovations, reaching a highly mature level. The industry boasts a group of experienced boiler professionals and technicians capable of providing timely and professional service support. Choosing coal-fired boiler technology for heating or industrial heat supply helps lower the technical acquisition threshold and reduces operational risks to a certain extent.

- Promoting Industry: A stable energy supply is crucial for many industrial sectors, especially in heavy industries and energy-intensive fields such as thermal power, chemicals, cement, steel, papermaking, food, textiles, and more. Coal-fired boilers are often the first choice in these energy-intensive areas.

- Continuous Technological Innovation: Coal-fired boilers now incorporate numerous new technologies aimed at burning hotter and cleaner, as well as better utilizing thermal energy and making the system easier to operate.

Innovations in Our Coal-Fired Boilers

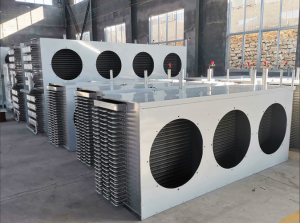

- New Energy Savers: Adopting condenser designs that recover heat from new sources, making the equipment more energy-efficient. The innovative condenser design overcomes issues of low heat dissipation efficiency and high energy consumption found in traditional condensers. By optimizing the heat dissipation structure and improving heat transfer efficiency, these problems are effectively resolved, ensuring more stable and reliable equipment operation and bringing considerable economic benefits to enterprises.

- Desulfurization and Denitrification Technology: Reduces harmful gas emissions, playing a significant role in environmental protection. Through a series of chemical reactions, sulfur and nitrogen compounds produced during coal combustion are converted into harmless substances, reducing atmospheric pollution. This not only aligns with current green and environmental trends but also earns enterprises a good social reputation.

- Improved Boiler Structure: Increasing the combustion area of chain grates and the contact area between boiler downcomers and heat sources, resulting in a larger heating area and improved thermal energy utilization. Firstly, the increase in the chain grate combustion area ensures a fuller combustion of fuel, reducing incomplete combustion phenomena. This not only improves boiler combustion efficiency and reduces fuel consumption but also decreases harmful gas emissions, benefiting environmental protection. Additionally, increasing the combustion area helps stabilize the combustion process, reducing boiler operational instability and enhancing equipment safety. Secondly, increasing the contact area between boiler downcomers and heat sources allows for more sufficient heat transfer, improving thermal energy utilization. This improvement brings significant effects in actual operation, enabling the boiler to generate more useful heat under the same conditions to meet production needs.

- Dust Removal Methods: Employed dust removal methods include ceramic multi-tube dust collectors, cyclone dust collectors, water film dust collectors, and bag dust collectors. These methods effectively reduce the smoke concentration emitted by coal-fired boilers, improving air quality and protecting the ecological environment. Ceramic multi-tube dust collectors utilize inertial collision principles to cause smoke particles to adhere to the tube walls when passing through the pipes at high speeds, achieving dust removal. Cyclone dust collectors separate smoke particles through cyclone effects. Water film dust collectors use water film adsorption and scrubbing to remove smoke particles. Bag dust collectors filter smoke particles through the filtering action of filter materials, blocking them outside the bags to achieve dust removal.

- Fully Imported PLC Intelligent Control System: Enhances the intelligent and automated level of coal-fired boilers. With cutting-edge control systems and sensor technology, the operational precision and efficiency of coal-fired boilers are significantly improved. By monitoring key parameters such as temperature, pressure, and flow in real-time, the system can automatically adjust fuel supply, air volume, water level, and other parameters to ensure stable boiler operation and efficient energy conversion. Additionally, the application of remote monitoring and fault diagnosis systems enables the timely detection and handling of potential issues during boiler operation, enhancing the reliability and safety of the boiler system.

In summary, in the energy sector, the status of coal-fired boilers cannot be overlooked. Despite rapid advancements in new energy technologies, coal-fired boilers, with their stable energy supply, relatively high economic efficiency, mature technology, and continuous innovation trends, still play a crucial role in many industries.

Looking ahead, with increasingly stringent environmental standards and continuous technological innovation, coal-fired boilers will develop in a more environmentally friendly, efficient, and intelligent direction, providing more stable and reliable energy security for various industries. For more information, visit http://www.boiler.ph.

Design Features of DZL Coal-Fired Steam Boiler

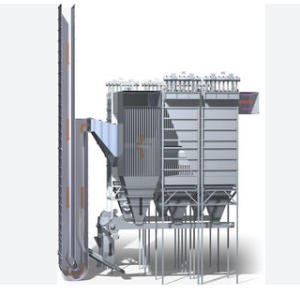

For the first type of boiler, we recommend the commonly used DZL chain grate steam boiler.

Core Design Features: The DZL coal-fired steam boiler features a single-cylinder, longitudinal chain grate design. “Single-cylinder” refers to the boiler having only one horizontal cylinder inside, distinguishing it from double-boiler designs which have two cylinders, one larger at the top and one smaller at the bottom. “Longitudinal” refers to the layout of the boiler’s water tubes. The water tubes are designed as vertical water-cooled walls near the furnace, directly absorbing heat from the grate and converting hot water into steam, which is then discharged from the upper horizontal cylinder to provide a stable heat source. These water-cooled walls effectively protect the boiler furnace from high-temperature erosion and also reduce the external temperature of the boiler.

The furnace is the core working area of the coal-fired boiler, with an internal sawtooth structure that allows coal to combine very fully with air. Temperature control inside the furnace is crucial to prevent high-temperature combustion of the grate. Therefore, a blower is installed at the bottom of the boiler to ensure a constant flow of fresh air for high boiler combustion efficiency.

Internal Space Design: High-temperature flue gas from the boiler is discharged through the smoke pipes, but it carries a significant amount of heat. Directly discharging it into the air would be wasteful, so an energy saver is usually equipped at the furnace exit. The flue gas enters the pipes, while softened water flows through the internal water pipes. The softened water is heated by the high-temperature flue gas to a certain temperature and then input into the boiler body, effectively improving the temperature of the hot water entering the boiler and thus enhancing the efficiency of the coal-fired boiler.

The chain grate allows coal to be evenly spread on top. It has an automatic speed adjustment box that allows coal to be slowly conveyed backward. During this process, the coal gradually burns out, providing a very stable feeding method that also improves coal combustion efficiency.

conclusion

In terms of safety performance, you can rest assured. Our DZL grate system is specially equipped with a design that prevents backfire and promotes complete combustion. It can precisely control the operating speed of the grate and flexibly and dynamically adjust the ratio of primary air to secondary air, effectively controlling combustion speed and temperature and significantly reducing the production of harmful gases and particulate matter due to incomplete combustion.

People are also more concerned about the cleanup of boiler cinders and daily maintenance. We have designed it with an automatic slag remover. After the coal is completely burned, the waste slag in the furnace is automatically guided to the slag remover, which is usually equipped with scraper or screw slag devices that automatically transport the cinders to the outside of the boiler in a fully automatic manner.

Of course, coal-fired boilers have many other advantages. Whether you need a large tonnage or a small tonnage, coal-fired boilers are a good choice for you. If you are unsure about the structure you need or the output capacity, our engineers can customize it for you.