Introduction

In this modern era, scientists are exploring sustainable energy sources that do not harm the environment. While many modern solutions, such as electricity, have proven helpful, traditional methods like burning wood for heat remain highly effective. Wood-fired steam generators are an excellent eco-friendly way to produce steam, making them a valuable option for industrial applications.

But the question remains: Are these wood-fired steam boilers truly useful? Let’s explore everything you need to know about wood-fired boilers in this guide.

What Is a Wood-Fired Steam Generator?

A wood-fired steam generator is a system that converts boiling water into steam. It is commonly used in industrial applications, ranging from small-scale projects to large-scale production.

The steam generator consists of a combustion chamber where the fuel—in this case, wood—is burned. This system can also operate using other fuels such as natural gas, oil, coal, or biomass.

To ignite the steam generator, you’ll need wood logs or pellets. Typically, the generator features a removable grate for easy wood loading, though the design may vary depending on the boiler’s size and brand.

Are Wood-Fired Steam Generators Suitable for Industrial Applications?

Yes, wood-fired steam generators are well-suited for industrial applications. They come in various sizes, with smaller units being standard for commercial and industrial use, while larger operations may require more powerful generators.

These systems are not limited to steam production; they can also generate hot water, depending on their capacity. Here are some common industrial applications:

- Sterilization

- Distillation

- Disinfection

- Production

Modern industrial wood-fired boilers offer advanced features, including compatibility with multiple fuel types such as biomass or coal. They also incorporate technologies like radiators, which enhance overall efficiency.

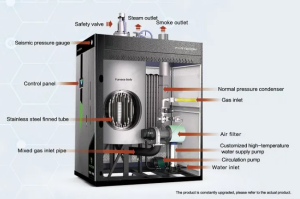

Components of a Wood-Fired Steam Generator

The effectiveness of wood-fired steam generators lies in their robust construction. Here are the key components and their functions:

1. Furnace

The furnace is responsible for burning wood and generating steam. It includes a wood storage unit for fuel.

2. Pellet Boiler Storage Tank

This tank stores steam or hot water for future use, making the generator cost-effective by optimizing industrial operations.

3. Cyclone Dust Remover

An automatic dust collector keeps the workspace clean by removing debris and preventing health issues.

4. Flue Gas Extractor

This component channels flue gases away from the system, maintaining optimal furnace temperature and operation.

5. Forced Draft Fan

The fan ensures a clean environment by generating mechanical air pressure for handling wood chips or pellets.

6. Water Treatment

This system removes harmful substances that could cause corrosion or foaming, prolonging the boiler’s lifespan.

7. Chimney

Essential for ventilation, the chimney releases toxic gases, ensuring a healthy work environment.

8. Grate Reducer

This component assists in fuel combustion by regulating airflow.

9. Ash Conveyor

The conveyor transports ash to a separate unit, minimizing physical hazards for workers.

10. Automated Control System (ACS)

Modern generators require minimal human intervention. The ACS optimizes performance, ensuring all components work seamlessly.

11. Additional Components

Auxiliary devices like dust removers, self-cleaners, FD/ID fans, valves, and economizers further enhance efficiency.

System Diagram

Equipment Names:

- Boiler

- Water Tank

- Decoxygenation Pump

- Economizer

- Cyclone Dust Remover

- Water Separating Header

- Chimney

- Deaerator

- Water Softener

- Feed Water Pump

- Energy-Saving Pump

Benefits of Wood-Fired Steam Generators

1. Energy Efficiency

Wood-fired boilers can achieve over 80% efficiency under optimal conditions, rivaling other steam generators.

2. Low Maintenance Costs

With self-cleaning components, these systems require minimal upkeep. Routine checks every two months are recommended.

3. Durability and Reliability

Using renewable wood as fuel, these generators are long-lasting and environmentally friendly.

4. Cost-Effective Energy

Wood is cheaper than alternatives like natural gas, making these boilers an affordable choice.

5. Safety Features

Protective coatings and efficient valves ensure operator safety and smooth adjustments.

Factors to Consider When Purchasing

1. Size

Smaller units are easier to install, while larger systems may require more manpower. Choose based on your industrial needs.

2. Auxiliary Parts and Spare Parts

Opt for reputable manufacturers like Boiler Philippines to ensure quality components and warranties.

3. Energy Efficiency

Select a generator with the right design and components to maximize efficiency (up to 86%).

4. Installation and Maintenance

Professional installation and reliable customer support are crucial for long-term performance.

5. Safety Standards

Prioritize boilers with protective features and fail-safe mechanisms.

Conclusion

The first step in choosing the right wood-fired steam generator is understanding your industrial requirements and budget. For a reliable solution, look no further than Boiler Philippines. We offer high-efficiency wood-fired steam generators in various sizes at competitive prices, along with exceptional customer support.

For more information, visit Boiler Philippines.